Your Cart is Empty

Customer Testimonials

-

"Great customer service. The folks at Novedge were super helpful in navigating a somewhat complicated order including software upgrades and serial numbers in various stages of inactivity. They were friendly and helpful throughout the process.."

Ruben Ruckmark

"Quick & very helpful. We have been using Novedge for years and are very happy with their quick service when we need to make a purchase and excellent support resolving any issues."

Will Woodson

"Scott is the best. He reminds me about subscriptions dates, guides me in the correct direction for updates. He always responds promptly to me. He is literally the reason I continue to work with Novedge and will do so in the future."

Edward Mchugh

"Calvin Lok is “the man”. After my purchase of Sketchup 2021, he called me and provided step-by-step instructions to ease me through difficulties I was having with the setup of my new software."

Mike Borzage

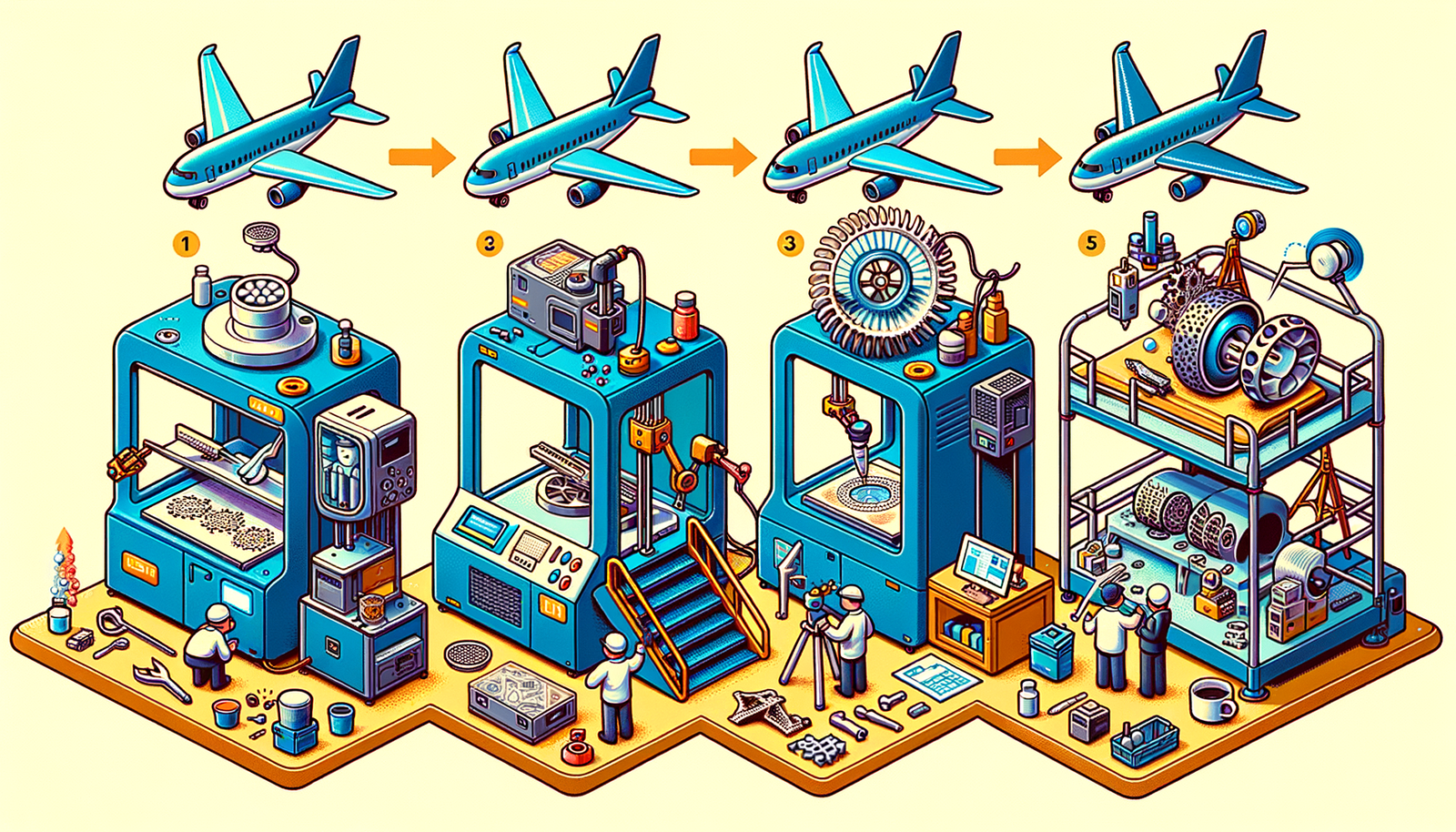

Design Software History: The Evolution of 3D Printing in Aerospace: From Prototyping to Production

November 27, 2024 7 min read

Introduction

3D printing, also known as additive manufacturing, has emerged as a transformative technology in various industries, with aerospace engineering standing at the forefront of its applications. The ability to create complex geometries and lightweight structures has significantly impacted how aerospace components are designed and manufactured. From its inception in the late 20th century, 3D printing has evolved from a tool for rapid prototyping to a viable method for producing critical components used in spacecraft and aircraft. This evolution reflects a paradigm shift in aerospace design, where traditional manufacturing constraints are overcome through the innovative use of additive technologies. The intersection of aerospace engineering and 3D printing not only accelerates the production process but also opens new possibilities for design optimization, performance enhancement, and cost reduction. Major aerospace corporations such as Airbus and Boeing have invested heavily in integrating 3D printing into their manufacturing processes, recognizing its potential to revolutionize the industry. Additionally, partnerships between aerospace companies and technology firms like GE Additive and 3D Systems Corporation have further advanced the application of additive manufacturing in aerospace. As the technology continues to mature, it is poised to play an even more significant role in shaping the future of aerospace engineering, influencing everything from component design to supply chain management.

The Development of 3D Printing Technologies

The journey of 3D printing technologies began in the early 1980s with the introduction of stereolithography (SLA) by Charles "Chuck" Hull, who later co-founded 3D Systems Corporation in 1986. Hull's pioneering work involved using ultraviolet lasers to cure photopolymer resins layer by layer, creating three-dimensional objects directly from digital data. This groundbreaking invention revolutionized the concept of rapid prototyping, allowing designers and engineers to quickly materialize their ideas without the need for traditional tooling. 3D Systems became one of the first companies to commercialize 3D printing technology, establishing a new industry that would grow exponentially in the following decades. In 1989, Scott Crump, co-founder of Stratasys Ltd., patented fused deposition modeling (FDM), a process that extrudes thermoplastic material through a heated nozzle to build objects layer by layer. FDM democratized 3D printing by introducing more affordable machines suitable for a broader range of applications. Around the same time, Dr. Carl Deckard at the University of Texas at Austin developed selective laser sintering (SLS), which uses a laser to sinter powdered materials, including plastics and metals. This technology was later commercialized by DTM Corporation, eventually acquired by 3D Systems. These advancements expanded the materials usable in 3D printing and opened the door for industrial applications, particularly in sectors like aerospace that demand high-performance materials and precision manufacturing.

- Stereolithography (SLA) - Invented by Chuck Hull in the 1980s, utilizing UV lasers to cure photopolymers.

- Fused Deposition Modeling (FDM) - Patented by Scott Crump in 1989, extruding thermoplastics through heated nozzles.

- Selective Laser Sintering (SLS) - Developed by Dr. Carl Deckard, using lasers to sinter powdered materials.

In the aerospace industry, specific 3D printing methods have gained prominence due to their ability to produce high-strength, lightweight metal components essential for flight applications. One such method is Direct Metal Laser Sintering (DMLS), developed by EOS GmbH, a German company founded by Dr. Hans Langer in 1989. DMLS uses a high-powered laser to micro-weld powdered metal alloys layer by layer, creating fully dense metal parts that meet the rigorous standards of aerospace applications. This technology enables manufacturers to produce components with complex internal features and optimized geometries that were previously impossible with traditional methods. Electron Beam Melting (EBM), patented by Arcam AB in Sweden, now part of GE Additive, is another significant technology in the aerospace sector. EBM utilizes a powerful electron beam to melt metal powders in a high vacuum environment, resulting in parts with excellent mechanical properties and minimal residual stresses. This method is particularly effective with materials like titanium alloys, highly valued in aerospace engineering for their strength-to-weight ratio. These technologies have allowed aerospace companies to innovate in design and manufacturing, leading to more efficient and capable aircraft and spacecraft.

Applications of 3D Printing in Aerospace Engineering

One of the primary applications of 3D printing in aerospace engineering is in the area of prototyping and rapid design iteration. The ability to quickly produce physical models from digital designs allows engineers to test and refine components more efficiently. This accelerates the development cycle and reduces costs associated with tooling and machining. Companies like Lockheed Martin and Northrop Grumman have embraced additive manufacturing for prototyping, enabling them to validate design concepts and perform functional tests earlier in the development process. Additive manufacturing facilitates the creation of complex prototypes that accurately represent the final product, including intricate internal structures. By reducing lead times and allowing for more design iterations, 3D printing enhances innovation and improves overall product performance. Additionally, the ability to produce prototypes on-demand reduces inventory requirements and supports more agile development methodologies.

Beyond prototyping, 3D printing is increasingly used for the production of complex parts and end-use components. The technology enables the creation of intricate geometries that are challenging or impossible to achieve with traditional manufacturing techniques. For instance, GE Aviation has utilized additive manufacturing to produce fuel nozzles for their LEAP engines. These nozzles, made using DMLS technology, are not only lighter but also more durable due to their monolithic construction, which eliminates the need for welding multiple parts. This results in improved performance and reduced maintenance requirements. Similarly, Airbus has incorporated 3D-printed brackets and components into their A350 XWB aircraft, taking advantage of the weight savings and material efficiency. The ability to create lightweight structures is particularly valuable in aerospace, where reducing mass directly contributes to improved fuel efficiency and payload capacity. Furthermore, 3D printing allows for the customization of parts to meet specific performance requirements, enhancing the overall effectiveness of aerospace systems.

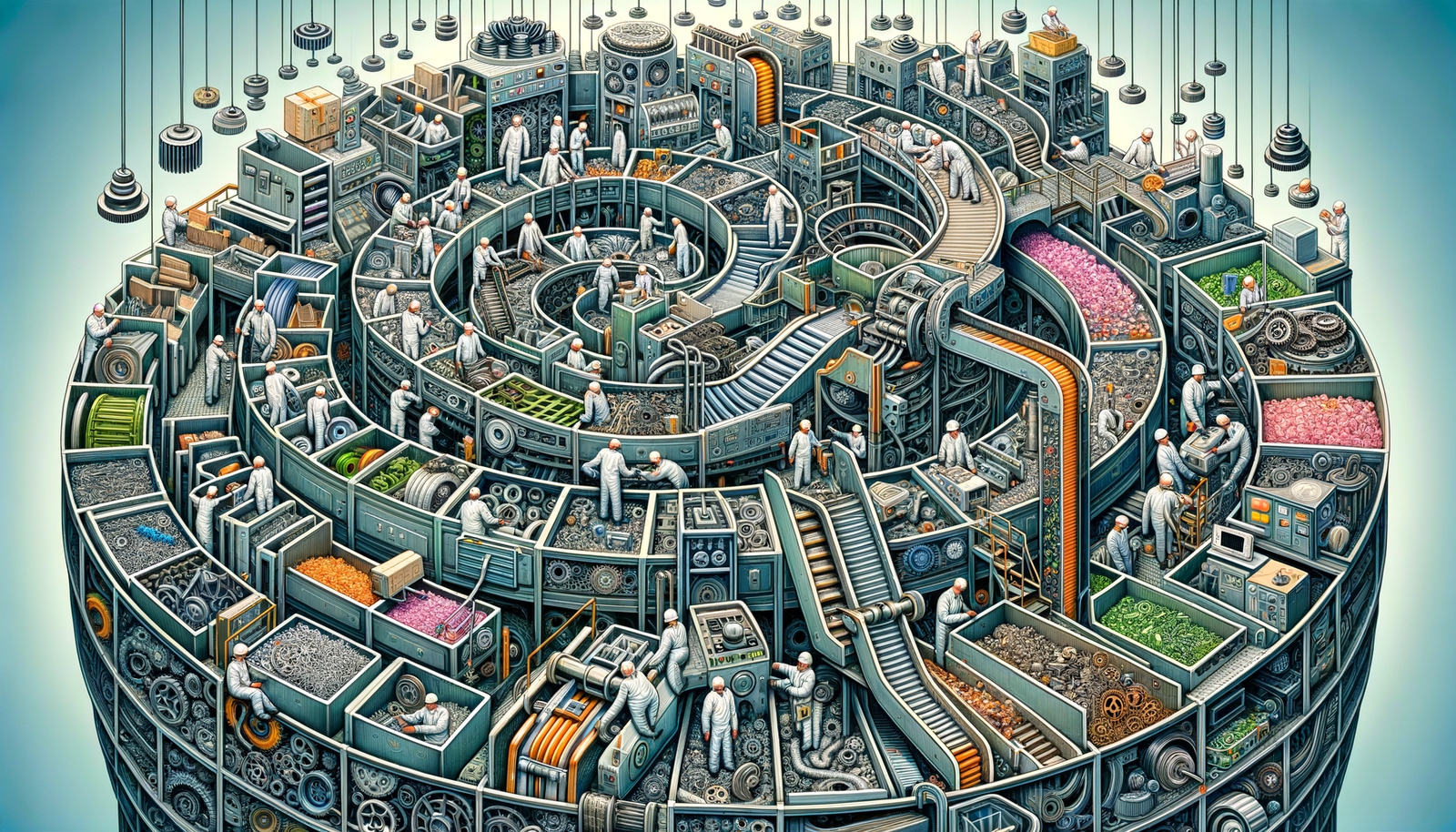

The integration of 3D printing with traditional manufacturing processes represents a collaborative approach to aerospace production. While additive manufacturing excels at creating complex and specialized components, traditional methods are still essential for producing certain parts at scale and achieving specific material properties. Aerospace companies are adopting a hybrid approach, where 3D-printed parts are integrated into assemblies produced by conventional means. This collaboration allows for the optimal use of each manufacturing method's strengths. For example, a component's core may be 3D-printed to benefit from complex internal structures and weight reduction, while the outer housing is machined for precision fits and surface finishes. This synergy enhances overall manufacturing efficiency and opens new avenues for innovation in aerospace design. Additionally, it allows companies to leverage existing manufacturing infrastructure while gradually incorporating additive technologies, facilitating a smoother transition and adoption.

Challenges and Future Directions

Despite the significant advancements, there are challenges that limit the widespread adoption of 3D printing in aerospace design. One major concern is the material limitations and mechanical properties of 3D-printed parts. While the range of printable materials has expanded, ensuring that these materials meet the stringent performance requirements of aerospace applications is critical. Issues such as anisotropy, where material properties vary depending on the build direction, can affect the reliability of components under stress. Moreover, discrepancies in material density and porosity can lead to weaknesses unacceptable in aerospace components, which must adhere to the highest safety standards. The development of standardized materials and processes is essential to address these concerns. Research institutions and companies like Fraunhofer Institute and Materialise are actively working on improving material quality and consistency in additive manufacturing.

Regulatory hurdles and certification processes present another significant challenge. Aerospace components must adhere to strict safety and performance regulations set by authorities like the Federal Aviation Administration (FAA) and the European Union Aviation Safety Agency (EASA). The certification of 3D-printed parts involves rigorous testing to verify that they meet all the required criteria for flight. Establishing standardized protocols for testing and quality assurance in additive manufacturing is essential. This process can be time-consuming and costly, potentially offsetting some benefits gained from rapid prototyping and production. Additionally, there is a need for developing comprehensive guidelines and standards specific to additive manufacturing, such as those being formulated by organizations like:

- ASTM International - Developing global standards for additive manufacturing processes and materials.

- Additive Manufacturing Standardization Collaborative (AMSC) - Coordinating efforts to standardize AM practices.

- International Organization for Standardization (ISO) - Establishing international standards to ensure quality and safety.

Looking to the future, additive manufacturing in aerospace is poised to make even greater strides, emphasizing sustainability and the development of new materials. The potential of advanced metal alloys specifically designed for 3D printing could enhance performance and reduce material waste. Research into high-strength, lightweight alloys like titanium aluminide and nickel-based superalloys is ongoing, with companies like Alloyed and Carpenter Technology Corporation leading the way. These materials offer superior properties suited for the demanding environments of aerospace applications, such as high-temperature resistance and strength-to-weight ratios. Additionally, advancements in composite materials and multi-material printing may open new possibilities for creating multifunctional components that integrate various material properties into a single part. The focus on sustainability also drives the exploration of recyclable and eco-friendly materials, aligning with the industry's goals to reduce its environmental footprint. Furthermore, the integration of artificial intelligence and machine learning in design and manufacturing processes promises to optimize additive manufacturing in aerospace further, enabling predictive maintenance and real-time quality control.

Conclusion

The revolutionary impact of 3D printing on aerospace engineering is undeniable. It has transformed traditional design and manufacturing paradigms, enabling the creation of complex, efficient, and lightweight components once beyond reach. The ongoing collaboration between aerospace manufacturers and additive technology developers continues to push the boundaries of what is possible. The importance of continued innovation and research in the field cannot be overstated, as overcoming current challenges will unlock new potentials. As the industry advances, we anticipate a future landscape where spacecraft and aircraft designs are reshaped by the capabilities of advanced 3D printing technologies. This evolution promises not only improvements in performance and efficiency but also a more sustainable and innovative aerospace industry, ready to meet the demands of the future. The integration of additive manufacturing is set to become a cornerstone of aerospace engineering, driving progress and enabling the exploration of new frontiers both in the sky and beyond.

Also in Design News

Cinema 4D Tip: Optimizing Workflow with Team Render in Cinema 4D

November 27, 2024 2 min read

Read More

Harnessing Advanced Nesting Algorithms for Sustainable Material Optimization in Design and Manufacturing

November 27, 2024 9 min read

Read MoreSubscribe

Sign up to get the latest on sales, new releases and more …